Our Approach

Magma Combustion Engineering adopts a flexible approach when producing customised designs which meet individual customer requirements. Effective and energy efficient designs are created whilst adhering to legislative, technical and safety standards.

The majority of projects are engineered and managed on a Turnkey basis including commissioning and after sales service. An active and dedicated team will maintain, service and give assistance to any site problems that may arise.

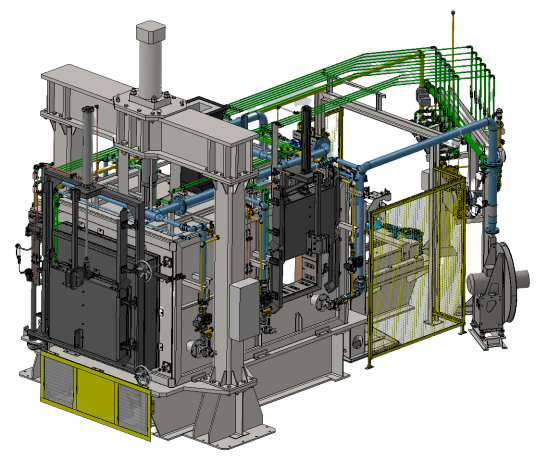

Magma Combustion Engineering's in-house design team uses leading 3D modelling and design software allowing us to fully model in 3D whilst being able to perform FEA and CFD studies to ensure equipment meets our customers requirements.

Thermal Equipment

- Heat Treatment Furnace

- Rotary Furnace

- Clam Furnace

- Walking Beam Furnace

- Walking Hearth Furnace

- Lift Off / Top Hat Furnace

- Pusher Furnace

- Bogie Furnace

- Roller Hearth Furnace

- Pit Furnace

- Continuous Mesh Belt Furnace

- Specialist Process Specific Equipment

- Tundish Heaters

- Ladle Heaters

- Galvanising Baths

- Regenerative Thermal Oxidiser (RTO)

- High Temperature Kilns (1700℃)

- Electric Ovens

- Die Heating Equipment

Not found what you are looking for? Contact us